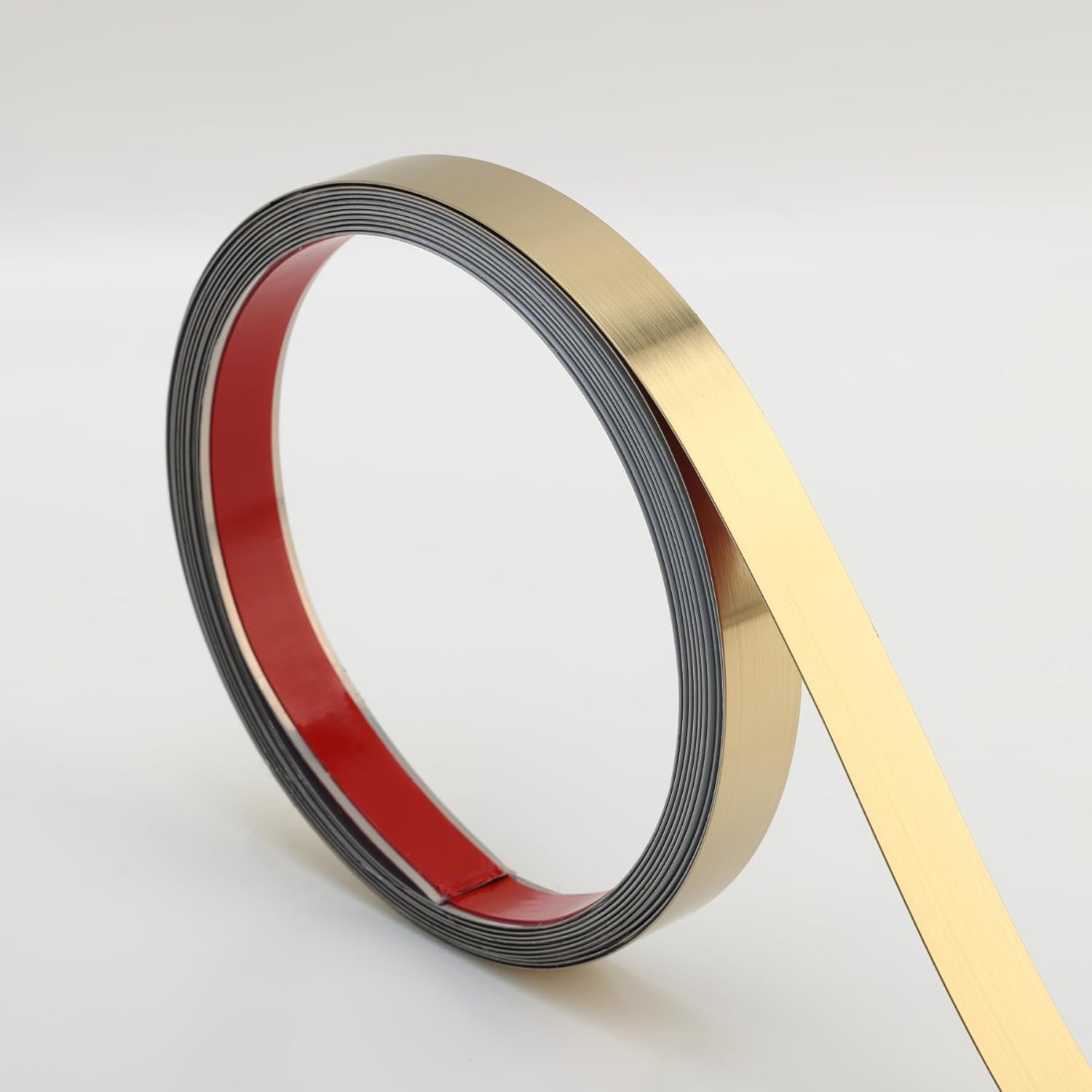

Stainless Steel Self Adhesive Strips

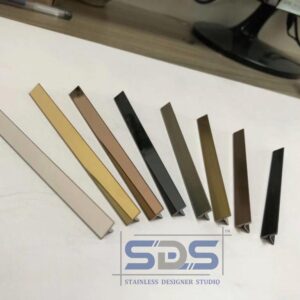

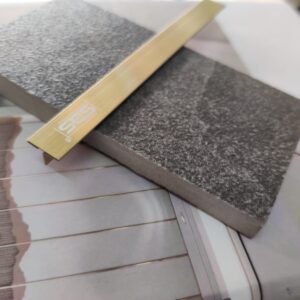

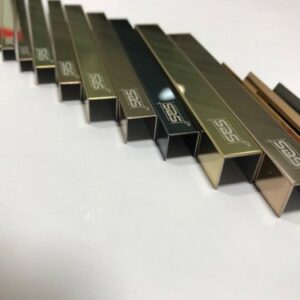

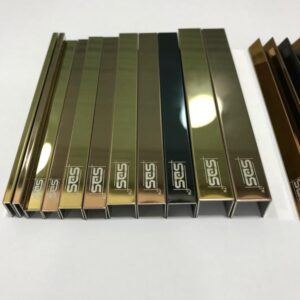

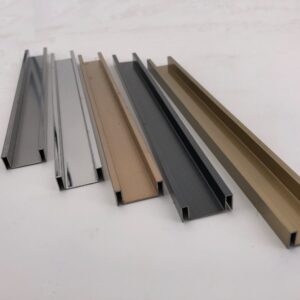

Transform any surface with SDS self-adhesive stainless steel strips, available in widths of 8mm, 10mm, 12mm, 20mm, and 25mm. These premium stainless steel strips offer a range of stunning color finishes: Gold, Rose Gold, Silver, and Black, making them ideal for a variety of decor styles. Each roll measures 5 meters, ensuring ample length for versatile applications in home, office, and commercial spaces. Designed for ease of installation, these self-adhesive strips provide a sleek, modern finish for enhancing surfaces like walls, furniture, glass, and cabinetry without the need for nails or screws.

Our stainless steel strips are crafted for durability and style, and they add a touch of elegance to any project. They are rust-resistant and built to withstand daily wear, making them suitable for both interior and exterior use. Ideal for DIYers, interior designers, and architects, SDS self-adhesive stainless steel strips offer a quick and efficient way to elevate the aesthetic of any space.

Key Features

Sizes Available: 8mm, 10mm, 12mm, 20mm, 25mm widths

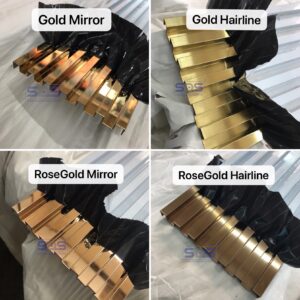

Color Options: Gold, Rose Gold, Silver, Black

Length: 5 meters per roll for seamless applications

Installation: Easy peel-and-stick, no additional tools required

Applications: Walls, mirrors, doors, furniture edges, cabinetry, glass surfaces, and more

Durability: Rust-resistant and long-lasting finish

FAQ Section for Self-Adhesive Stainless Steel Strips by SDS

Q: What surfaces can I apply these self-adhesive stainless steel strips to?

A: These strips are suitable for various surfaces, including painted walls, mirrors, furniture, glass, plastic, wood, and metal. For best adhesion, ensure the surface is clean and dry before application.

Q: Can I cut these strips to a specific length?

A: Absolutely! These strips can be easily cut to your desired length with basic tools like scissors or a utility knife.

Q: Do these strips leave any residue when removed?

A: SDS self-adhesive stainless steel strips are designed to be removable without leaving sticky residue, though this may vary based on the surface and duration of use.

Q: Are these strips suitable for use in humid areas like bathrooms?

A: Yes, these stainless steel strips are ideal for humid areas, as they are rust-resistant and durable.

Q: Can I use these strips for DIY home decor projects?

A: Absolutely! These strips are perfect for DIY projects, allowing you to add an elegant, modern look to any room or surface without professional installation.

Self-adhesive stainless steel strips

Peel and stick stainless steel trim

Gold stainless steel strips for walls

5-meter stainless steel tape

Decorative stainless steel edging

DIY stainless steel strips

General Technical Data Sheet: PVD Coating for Stainless Steel

Product Overview

Physical Vapor Deposition (PVD) coating is a highly advanced coating process that enhances the durability, aesthetic appeal, and functional performance of stainless steel surfaces. PVD coating is applied under vacuum conditions, creating a thin, durable layer that provides a variety of finishes and colors, making it ideal for applications in architecture, interior design, and other high-end uses.

Technical Specifications

Base Material: Stainless Steel (typically AISI 304, 316, or 201, 430 grades)

Coating Process: Physical Vapor Deposition (PVD) under vacuum

Coating Thickness: 0.5 – 5 microns

Color Options: Gold, Rose Gold, Black, Bronze, Blue, Gunmetal, Silver

Adhesion Strength: High (passes tape and cross-hatch tests)

Corrosion Resistance:

Salt Spray Test (ASTM B117): Up to 1000 hours

Humidity Test: Up to 2000 hours

Hardness: Typically 1500 – 2500 HV (Vickers Hardness)

Scratch Resistance: High; withstands abrasion with a pencil hardness of up to 9H

Temperature Resistance: Up to 600°C

Surface Finish: Can be applied to mirror, satin, or brushed finishes

Eco-friendliness: PVD is an environmentally friendly process with no hazardous chemicals or waste

Properties and Benefits

Durability: PVD coatings significantly enhance the durability of stainless steel, making it resistant to wear, scratches, and corrosion.

Aesthetic Versatility: Offers a wide range of colors and finishes, from classic metallic tones to vibrant, contemporary colors.

Eco-friendly Process: PVD does not produce hazardous waste and is more environmentally friendly compared to traditional plating methods.

Corrosion Resistance: Protects against rust and tarnishing, even in harsh environments, due to a highly resilient coating.

Hypoallergenic: Suitable for applications in the food and medical industries as it does not release toxic substances.

Applications

Architecture: Cladding, elevators, door frames, and facades

Interior Design: Wall panels, furniture, fixtures, and decorative trims

Appliances: Handles, knobs, and appliance trim

Automotive: Exterior trims, logos, and interior detailing

Jewelry and Watches: Used for high-end jewelry due to its durability and hypoallergenic properties

Performance Testing

Scratch and Abrasion Resistance: Passed 9H pencil hardness test

Corrosion Testing: Salt Spray Test for 1000 hours; shows no signs of rusting or degradation

Adhesion Testing: Cross-hatch tape test passed with zero delamination

Temperature Stability: Withstands up to 600°C, making it ideal for applications exposed to high heat

Cleaning and Maintenance

Cleaning: Use a soft micro fibre cloth with a mild detergent and water. Avoid abrasive cleaners and tools that may damage the coating.

Maintenance: PVD-coated stainless steel surfaces are low-maintenance and retain their appearance over long periods with basic care.

Safety Information

PVD coating is a safe, environmentally friendly process that does not involve toxic or hazardous chemicals. It produces no waste or emissions and is safe for both interior and exterior applications.